Laser engraving technology has evolved at a breakneck pace. From simple text etching to intricate 3D designs, the possibilities seem endless. Staying informed about these advancements is crucial for businesses and hobbyists alike. This blog post will delve into the latest laser engraving trends and technologies shaping the future of laser engraving machines, equipping you with laser engraving technology developments to stay ahead of the curve.

Overview of Laser Engraving Technology

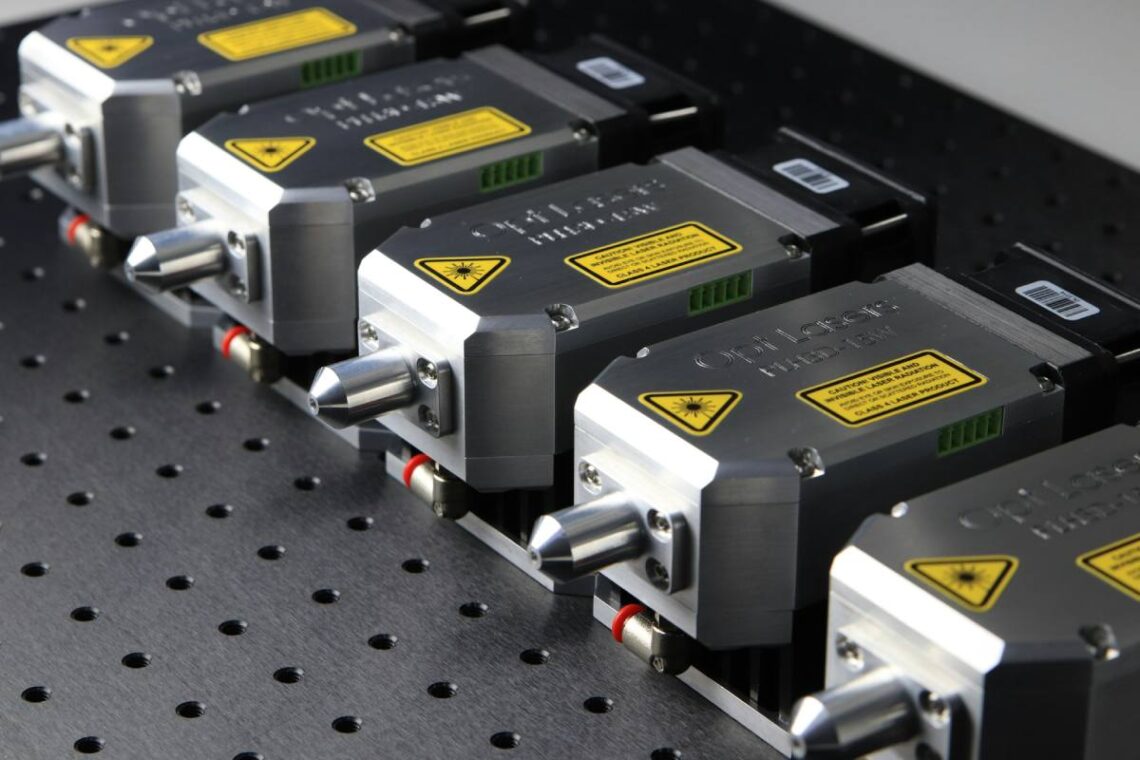

Traditional laser engraving involves directing a focused laser beam onto a material, vaporizing the surface to create a permanent mark. This laser engraving technology is widely used for marking metals, plastics, wood, and other materials. Key components include a laser source, focusing optics, and a computer-controlled movement system. The laser beam is guided across the material, creating intricate designs or text.

Recent Innovations in Laser Engraving Technology

What trends in laser engraving are grabbing attention? Let’s dig into the details of laser engraving technology:

Fiber Lasers

Fiber lasers have gained popularity in laser engraving due to their higher efficiency, faster processing speeds, and ability to engrave on a wider range of materials. Unlike traditional CO2 lasers, fiber lasers have a smaller beam diameter, allowing for more precise engravings. They also generate less heat, making them suitable for heat-sensitive materials like plastics and acrylics.

Higher Power Lasers

Higher-powered lasers can engrave deeper and faster, allowing for more intricate designs and shorter production times. This is especially beneficial for applications requiring detailed markings or large-scale production.

Improved Software and Design Tools

User-friendly software allows for easy creation of complex designs, including 3D models and vector graphics. Integration with other digital tools streamlines workflows, enabling seamless transitions from design to production. This empowers users to create highly customized and intricate engravings efficiently.

Hybrid Laser Systems

These systems offer greater versatility for users, enabling them to create a wider range of products and applications. For example, a laser engraving machine with integrated cutting capabilities can efficiently create custom-shaped products with intricate designs.

Automation and Robotics

Robotic systems and AI in laser engraving can handle complex tasks like material handling, loading, and unloading, reducing manual labor. This streamlines production, improves efficiency, and ensures consistent quality. It also enables integration with other manufacturing processes, creating a more efficient and streamlined workflow.

3D Laser Engraving

3D laser engraving adds a new dimension to design by creating depth and texture. This technology allows for the creation of intricate, three-dimensional engravings, opening up new possibilities for creativity and customization.

Benefits of Innovations in Laser Engraving

Enhanced Efficiency

Faster laser engraving speeds allow for more efficient production, while automation reduces manual labor and streamlines workflows. This leads to shorter lead times and higher output, benefiting both businesses and customers.

Greater Material Compatibility

Laser technology advancements have expanded the range of materials that can be engraved. From metals and plastics to glass, ceramics, and even leather, the possibilities are endless. This opens up new avenues for creative applications and customization, enabling businesses to offer a wider range of products

Cost Savings

Improved efficiency, faster processing speeds, and lower maintenance requirements can contribute to cost savings. This makes laser engraving more accessible to small businesses and individuals, expanding the potential for creative applications and entrepreneurship.

Improved Design Flexibility

Software advancements empower users to create more complex and intricate designs with ease. This increased creativity and customization allow for unique and personalized engravings, meeting the diverse needs of businesses and individuals.

Challenges and Considerations

The laser engraving machine looks fascinating, but like every technology, even these developments in laser engraving have brought its share of challenges and considerations:

Initial Investment Costs

Upgrading to the latest laser engraving technology can be costly. Businesses should carefully evaluate the potential return on investment by considering factors such as increased production efficiency, expanded product offerings, and potential cost savings over time.

Learning Curve

Adopting new laser engraving technology may require additional training for users familiar with older systems. Familiarizing yourself with new software, hardware, and techniques can ensure efficient operation and maximize the benefits of the latest innovations.

Maintenance and Support

Regular servicing, software updates, and troubleshooting can ensure optimal performance and minimize downtime, maximizing the benefits of your investment.

Future Trends in Laser Engraving Technology

Integration with AI and Machine Learning

AI can revolutionize laser engraving by automating design tasks, optimizing production workflows, predicting maintenance needs, improving quality control, and enabling new creative possibilities.

Sustainability Initiatives

The laser engraving industry is increasingly focused on sustainability. This includes using eco-friendly materials and adopting practices that reduce waste, energy consumption, and environmental impact.

Personalization and Customization

Innovations in laser engraving will enable businesses to offer highly personalized products, catering to individual preferences and enhancing customer satisfaction.

If you want laser engraving technology assistance, then contact Max Laser, and their team will guide you better.

Conclusion

There is no doubt in the fact that laser engraving technology is evolving quickly. Companies need to stay informed about innovations to outshine the market, as that will offer them a chance to explore new possibilities for materials, efficiency, and design.